testing by torsion steel 45 c|mild steel torsion test results : companies Experiment Two- Torsional test Experiment Two (2) Torsional testing of Circular Shafts Introduction: Torsion occurs when any shaft is subjected to a torque. This is true whether the shaft is rotating . Shear Modulus G and Torsional Stress for Steel and Aluminum. A. Using the reading of above to calculate the shear modulus and torsional stress .

web23 de dez. de 2022 · Quem é MC Pipokinha, dona do show com coreografias sensuais insanas. Trechos do show da MC Pipokinha se tornaram virais nas redes sociais. A apresentação é marcada por .

{plog:ftitle_list}

web29 de mar. de 2023 · Aline Mineiro onlyfans mostrando o rabo MixPutaria.com tem os melhores videos pornográficos, assista agora vídeos porno de famosinhas da internet .

For this experimentation we used two cylindrically tapered rods of cast iron and mild steel. Each was torsion tested in the Tinius Olson Torsion Machine. The following lists the steps that are need to test each material and obtain the data needed to derive several .

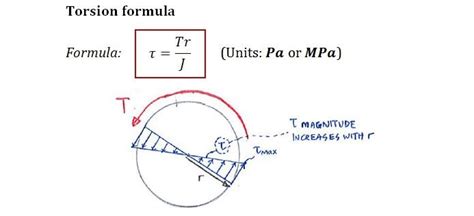

Chapters 2 and 3 provide an overview of the fundamentals and basic theory of torsional loading for structural steel members. Chapter 4 covers the determination of torsional stresses, their .m) or foot-pound force (ft

EQUIPMENT & MATERIALS 3.1 Equipment Torsion Tester Machine 3.2 Materials Aluminum & Mild Steel ENT 251/4 – Solid Mechanics Laboratory Module 15 Fig. 1 Torsion test machine 3. TORSION TEST The . 13. Torsional Strain, y: Strain corresponding to specified torque in torsion test. It is equal to torsional deformation multiplied by the radius of the shaft. It's units are radians. 14. Torsional Stress, T: Shear stress developed in .Experiment Two- Torsional test Experiment Two (2) Torsional testing of Circular Shafts Introduction: Torsion occurs when any shaft is subjected to a torque. This is true whether the shaft is rotating . Shear Modulus G and Torsional Stress for Steel and Aluminum. A. Using the reading of above to calculate the shear modulus and torsional stress . Spheroidizing annealing and torsion testing of 0.027 wt% carbon steel rod were conducted to evaluate spheroidization kinetic behavior at 943 K (670 °C) under deformed and non-deformed states.

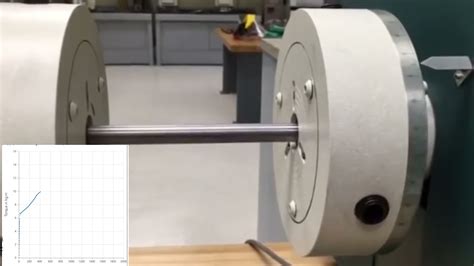

called helical fracture) would be tensile (45° splitting). Equipment This experiment is performed using The SM1001 30Nm Torsion Testing Machine shown in the figure below. Figure 2: SM1001 30Nm Torsion Testing Machine . Specimen Setup 1. Accurately measure and record the dimensions of your specimen. . Carbon Steel . 2. Press the ‘Peak Hold . Introduction. Torsion test is carried out to determine the shear modulus of structural materials, such as steel and aluminum. Shear modulus is a material property that is useful in calculating the compliance of structural materials in torsion, provided that they follow Hooke’s law; that is, that the angle of twist is proportional to the applied torque.ME 354 LAB #4: DISCUSSION OF THE TORSION TEST Each lab section performed a torsion test of a cylindrical 6061-T6 aluminum specimen. The specimen was mounted in a Technovate model 9041 Torsion Tester. A top view is shown in Figure 1. The cylindrical specimen was clamped in two 52.3 mm dia grips. The top grip was

tests for hardness

In the laboratory course, we use 1018 cold rolle d steel specimens for demonstration whereas students in groups of three c onduct the test on 2024-T351 alumin um alloy specimens. Table 1 below summarizes the results from least-square s line fitting for both steel and aluminum alloy specimens: Table 1: Results from Ex perimental Measurementsvii Contents Foreword v Contents vii summary ix IntroduCtIon 1 1.1 Torsion of beams 1 1.2 Scope of this publication 2 1.3 Terminology and symbols 3 1.4 References to Eurocode 3 4 elastIC theory oF torsIon 7 2.1 St Venant torsion 7 2.2 Warping torsion 9 .

The torsion test is a mechanical test method used to examine the deformation of a specimen through a twisting/rotating motion.. Torsion, in its simplest form, is the action of twisting. Many everyday materials, components, component assemblies, and end-user products used in various industries are designed with the primary purpose of supporting this direction of movement.

Torsion Testing of Structural Metals . • Permanent marker • Specimens: 1018 steel (tube) and 6061-T6 aluminum (rod) • Safety glasses Figure 1.2.1. T-O Lo-Torq torsion machine Experimental Procedure 1. Obtain one steel and one aluminum specimen and label them for your group andaddition of a torsion test module to our Horizon software allows complete machine control along with capture and analysis of the resultant torsional test data, showing the material behaviour throughout the test. Torsion tester for testing samples up to 7ft/2.1m long and 5in/125mm diameter. The machine is shown with the optional PC-based software.One of the most common examples of torsion in engineering design is the power generated by transmission shafts. We can quickly understand how twist generates power just by doing a simple dimensional analysis.Power is measured in the unit of Watts [W], and 1 W = 1 N m s-1.At the outset of this section, we noted that torque was a twisting couple, which means that it has .In torsion testing, it is also necessary to provide the mechanical coupling between the specimen and clamping. . Work E, Dolan TI (1953) The influence of strain rate and temperature on the strength and ductility of mild steel in torsion. Proc ASTM 53:611–626. Google Scholar Greene OV, Stout RD (1940) The stress-strain characteristics of the .

torsional shear stress pdf

Torsion testing involves the twisting of a sample along an axis and is a useful test for acquiring information like torsional shear stress, maximum torque, shear modulus, and breaking angle of a material or the interface between two materials. . The 0.45% C-steel (Figure 2.25A) shows a continuous chip formation and no adiabatic shear failure .CFFT Samples. The 1800 mm long CFFT samples (Fig. 3) have their ends embedded into 400 mm long end blocks made of concrete-filled steel sections forming a dumbbell shape, resulting in a 1000 mm testing section.End blocks, commonly used with circular sections [26, 28], provide a mounting surface for the clamped loading brackets and a means to transfer torsion to the . Advanced Technologies for Quality Control and Testing in Torsion Springs. The manufacturing and testing of torsion springs have significantly advanced with the integration of modern technologies. These advancements ensure higher precision, reliability, and efficiency in quality control and testing processes. 1. Automated Inspection Systems

EN 1.0503 Material C45 Steel. EN 10083-2 C45 steel (EN 1.0503) is a high strength medium carbon quality steel. Due to poor hardenability, C45 material is generally used in a normalized condition, and when the mechanical properties are required to be high, the quenching and tempering treatment is adopted.Torsion tests twist a material or test component to a specified degree, with a specified force, or until the material fails in torsion. The twisting force of a torsion test is applied to the test sample by anchoring one end so that it cannot move or rotate and applying a moment to the other end so that the sample is rotated about its axis. R.S. Khurmi & J.K. Gupta (2005) stated when an engineering component is subjected to twisting moment or torque then it is said that the engineering component is under torsion. Stress produce as a result of torsion are called torsional shear stress. Torsional shear stresses are maximum at outer surface ad minimum at the central axis. (pg 120-121)

To conduct torsion test on mild steel. Apparatus:- 1. A torsion test machine along with angle of twist measuring attachment. 2. Standard specimen of mild steel. 3. Steel rule. 4. Vernnier caliper or a micrometer. Theory:- For transmitting power through a rotating shaft it is necessary to apply a turning force. .IS 1717 (2012): Metallic Materials - Wire - Simple Torsion Test [MTD 3: Mechanical Testing of Metals] IS 1717 : 2012 . Steel Copper and copper alloys Aluminium and aluminium alloys 1 5 2 1,5 0,5 1 d (D) < 1 . 45 mm wide by 20 mm thick by a length slightly less than the free length between the grips given in Table 2,

Torsion Test on Mild Steel | KTU S4 Material Testing Lab | Experiment Setup

Torsion Tester provide loading & weighing capabilities in both directions of rotation with variable speed drive loading system, digital control & indicating system in a fixed unit. . Tinius Olsen offers a full range of torsion testing machines in capacities from 10,000-300,000in.lbf or kg.cm (1000-30,000N.m). . 14-115°F (-10- 45°C .ME 354 LAB #4: DISCUSSION OF THE TORSION TEST Each lab section performed a torsion test of a cylindrical 6061-T6 aluminum specimen. The specimen was mounted in a Technovate model 9041 Torsion Tester. A top view is shown in Figure 1. The cylindrical specimen was clamped in two 52.3 mm dia grips. . 45 . Table 2: Experimental measurements and .Torsion Testing Machine (30 Nm) SM1001 Benchtop machine to allow students to do torsion tests on diff erent materials. Demonstrates . • TR1011: 0.1% carbon steel, normalised at 900°C • TR1021: 0.40% carbon steel, normalised at 860°C • TR1040: Brass 60Cu/40Zn, half hard

tests for hardness at home

torsion testing of steel

torsion testing of cast iron

tinius olson torsion testing

Jovem é preso em flagrante por matar e decepar mãos de padrasto. Geral. BNews abre 2024 na liderança absoluta entre sites jornalísticos da Bahia; confira números. . Simm .

testing by torsion steel 45 c|mild steel torsion test results